Printed Circuit Boards (PCBs) are at the heart of modern electronics, playing a vital role in industries ranging from consumer gadgets to aerospace. As the demand for smart devices, automotive electronics, and industrial automation grows, so does the significance of efficient PCB manufacturing. In Singapore, a regional hub for electronics and semiconductors, the economics behind PCB production reveal interesting dynamics. Choosing the right PCB supplier in Singapore can make a major difference in ensuring both quality and cost-effectiveness.

Understanding The Cost Structure Of PCB Manufacturing

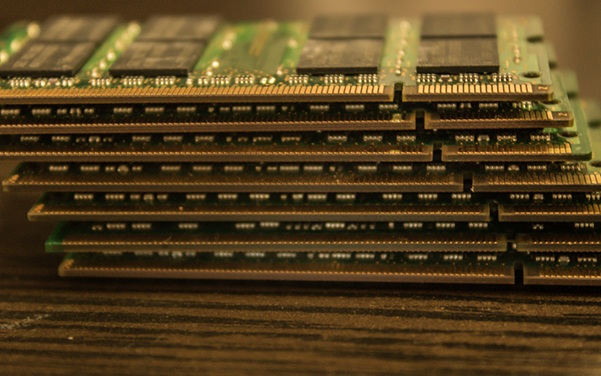

The economics of PCB manufacturing begin with a complex web of material procurement, labour costs, machinery investments, and compliance with quality standards. Raw materials, including copper-clad laminates, resins, and solder masks, form a significant portion of production expenses. Fluctuations in global commodity prices directly affect the overall cost of a single PCB unit.

Labour costs in Singapore are generally higher than in other parts of Southeast Asia, but local manufacturers benefit from a skilled workforce and advanced technology adoption. Automation has helped balance the higher wage structure, reducing the reliance on manual labour for repetitive tasks such as drilling or surface mount technology (SMT) placement.

Capital expenditure is another core factor. High-end equipment for etching, testing, and inspection is crucial for precision manufacturing. While these upfront investments are substantial, they reduce wastage and enhance productivity over time.

Supply Chain Considerations In A Global Landscape

Singapore’s strong logistics infrastructure makes it an attractive destination for electronic manufacturing. The ease of importing materials and exporting finished PCBs boosts efficiency for businesses that operate under tight deadlines. Moreover, many local manufacturers maintain ISO and IPC certifications, offering reassurance to overseas clients about their compliance and quality control.

However, recent global disruptions have highlighted the risks of over-reliance on international supply chains. This has led many companies to rethink sourcing strategies and engage more closely with a dependable PCB board manufacturer in Singapore. By working locally, companies can reduce delays and mitigate the uncertainties tied to global freight and raw material shortages.

Economies Of Scale In PCB Production

Volume plays a critical role in shaping the economics of PCB production. Manufacturing a small batch of PCBs can be significantly more expensive per unit compared to a larger order. Fixed costs like tooling, testing, and setup time are spread over a greater number of boards in large-scale production, making each piece cheaper.

This pricing model encourages companies to forecast their demand and place bulk orders to optimise costs. For startups or SMEs, this can be a challenge, but working with local partners can help navigate these limitations. Many Singaporean PCB suppliers offer flexible production runs and prototyping services to cater to varying business needs.

Innovation And Its Economic Impact

Technological innovation has transformed PCB manufacturing, especially in high-frequency, flexible, and multilayer board designs. With the Internet of Things (IoT) and 5G rolling out across different industries, the demand for advanced PCB architectures is rising rapidly.

As complexity increases, so does the cost, not only in terms of material use but also the need for enhanced design verification and testing processes. Yet, this also presents an opportunity for differentiation. Manufacturers that invest in R&D and maintain tight control over the production process can offer unique value propositions and command premium prices.

Working with a PCB supplier in Singapore that prioritises innovation and process improvement allows businesses to stay ahead of their competition without compromising on reliability or performance.

Environmental And Regulatory Economics

Modern PCB manufacturing cannot ignore the economic implications of environmental regulations. From proper waste management to the use of lead-free solder, manufacturers must comply with strict local and international standards.

Though environmentally compliant processes often require greater investment, they also unlock access to eco-conscious markets, especially in Europe and North America. Companies that factor in sustainability from the start are not only fulfilling regulatory obligations but are also strengthening their global competitiveness.

Strategic Partnering For Long-Term Value

Beyond cost considerations, forming strategic partnerships with a local PCB board manufacturer in Singapore can unlock long-term value. These collaborations promote transparency, ensure better communication, and allow for quicker design iterations and testing cycles.

For high-mix, low-volume industries such as aerospace or medical devices, these partnerships are essential. They support fast prototyping, design consultation, and supply chain alignment — all of which contribute to long-term business agility and financial sustainability.

Conclusion

The economics of PCB manufacturing are deeply influenced by factors such as scale, innovation, labour, material costs, and regulatory compliance. Singapore’s robust ecosystem of suppliers and manufacturers makes it a strong contender in the global PCB landscape. By aligning with a reliable PCB supplier in Singapore, businesses can better manage costs, quality, and supply chain risks while staying adaptable to future needs.

Contact MPN Tech today to explore efficient and cost-effective PCB solutions.

Comments